Specialized company for disposal

How the biowaste treatment plant works

The presorting

The biowaste is first delivered to the reception hall. Here it is crushed and then freed from metallic foreign matter by means of an overband magnet. These go directly from the composting plant to the recycling plant. Coarse impurities such as bags and sacks are screened as far as possible. The material thus prepared, which is low in foreign matter, can now be fed into the process.

Depending on its consistency, the biowaste is either sent to the composting or to the fermentation unit. Damp, low-structure waste first goes through the fermentation process before it enters the composting unit. Green waste and garden waste - both materials with a high structure - can be composted directly.

The composting technique

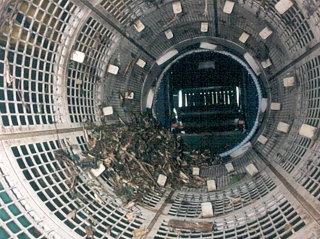

All waste intended for composting - materials rich in structure and fermentation residue - is transported by a conveyor belt into airtight encapsulated rotting tunnels. Depending on the status of the rotting process, a defined amount of air is supplied via an aeration floor, which flows through the rotting material. This eliminates the need to move the material. The exhaust air is dedusted by an air washer and biologically cleaned by a biofilter. Only then does it escape via the chimney. After passing through the fermentation or composting unit, the compost is then further processed. The last non-degradable materials such as foils and stones are finally removed by screening, air separation and hard material separation.

The fermentation technique

On the way to the fermentation unit, the waste is temporarily stored in a bunker. The feeding of the fermentation unit is fully automated. Therefore, material is constantly fed around the clock, even on weekends and holidays. This has a positive effect on the stability of the biology in the fermentation. Before the waste is transferred from the intermediate bunker to the fermentation container, it is mixed by a mixer to a pumpable mass with a defined dry substance content. The fermentation technique used is a single-stage dry fermentation process. The various microbial conversion processes from hydrolysis to methanogenic fermentation take place without spatial separation from each other. The average process temperature is 55 - 57 °C (thermophilic operating temperature). The fermented material is dewatered using screw presses and high-performance centrifuges. With a dwell time in the fermentation tank of up to three weeks, a hygienized compost is demonstrably produced, which bears the RAL seal of approval. 100% of the water produced during dewatering is returned to the process. The process is fresh water neutral and free of waste water. The biogas released during the fermentation process is fed into the two company-owned combined heat and power plants. Heat and electricity are produced there.